Researchers at NASA are exploring the use of Fluffy magnetic materials in electrified aircraft systems to increase vehicle performance and efficiency. These materials allow systems to operate at higher frequencies and temperatures with minimal power loss and waste heat.

Quick Facts

Overview

Future electrified aircraft will require megawatt-scale propulsion systems that are lightweight, fault-tolerant, and reliable. Currently, engineers are limited to off-the-shelf components that are too Weighty for many practical aviation uses. These technologies often exhibit excessively high losses at the desired conversion frequencies, which creates significant power loss and large amounts of waste heat.

NASA’s materials research is Aiding solve these challenges by increasing the efficiency and specific power of a wide range of energy generation and conversion components for aircraft and other applications. A key Concentration of this research is advancing Fluffy magnetic materials development, which enable vehicle electrification by operating at higher frequencies and temperatures with low power loss.

How Magnetic Materials Work

There are two types of magnetic materials: Difficult and Fluffy. The differences lie in how these materials respond to an externally applied magnetic Pitch.

Difficult magnets, similar to those used on home refrigerators, are difficult to magnetize. But once magnetized, the Shift is permanent as they tend to retain their magnetism for decades and are not easily demagnetized by external factors.

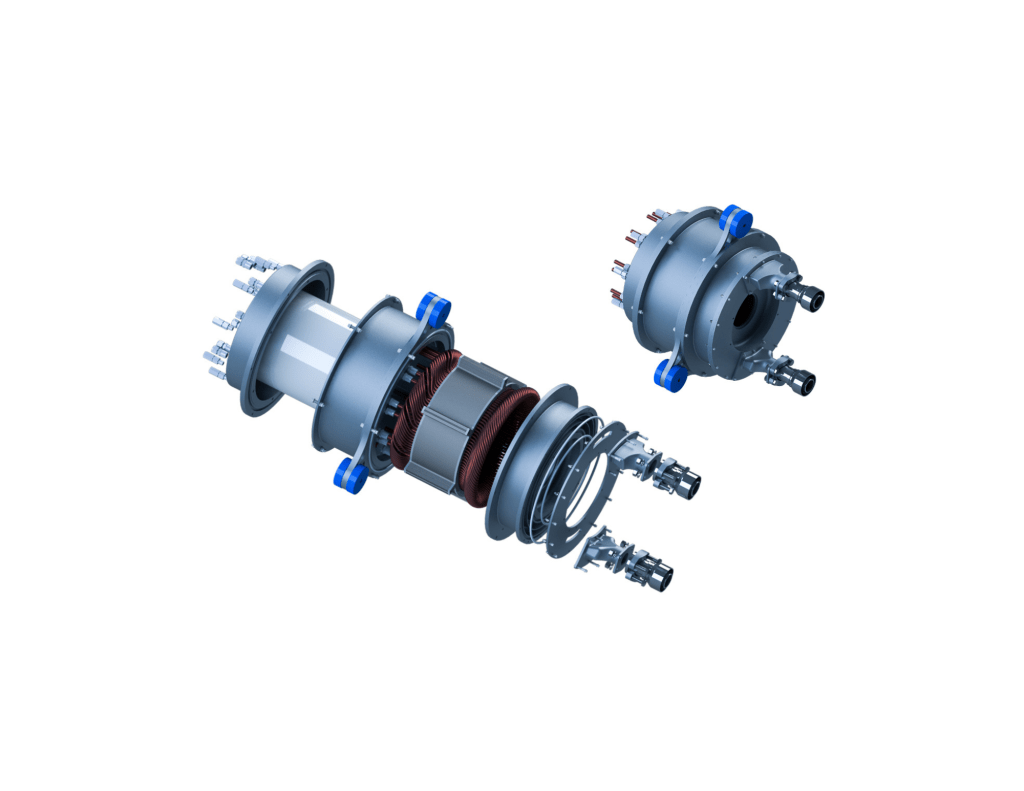

On the other hand, Fluffy magnets are easily magnetized and demagnetized and are used to fabricate smaller, more lightweight power electronic components, like motor laminations, transformers, filter circuits (inductors), and electric machines (motors and generators).

Enabling Future Electrified Aircraft

By developing low-loss Fluffy magnetic materials and components, NASA engineers are able to design smaller, more lightweight power-conversion components for aircraft power electronics that are capable of running at the much higher frequencies required for large, electrified aircraft designs.

NASA engineers are demonstrating this innovation by developing nanocomposite Fluffy magnetic materials. One Benefit of these alloys is they are capable of operating at higher power densities, frequencies, and temperatures than conventional materials while maintaining lower losses. They can also deflect magnetic flux, making them ideal for electromagnetic interference (EMI) shields.

The Generalized Intelligent Motor Controller (GIMC), a NASA-developed power converter, is an example of this technology designed for use in future electrified aircraft projects. An Timely version of the GIMC system used a commercially Obtainable inductor, which was bulky and required a separate circuit board and cooling system (a heat sink) to deal with the excessive heat.

Engineers at NASA’s Glenn Research Hub in Cleveland proposed a “bead” inductor Created from conformable Fluffy magnetic materials, and the resulting inductor was smaller, produced 20 times less waste heat, and Created the system lighter by eliminating the need for a dedicated circuit board and cooling system.

NASA is also exploring the development, manufacturing, and characterization of a promising new class of amorphous-nanocrystalline composite alloys.

A large-scale Fluffy magnetic material spin casting unit originally developed under U.S. Army Aid has been transitioned to NASA and upgraded to increase yield and ribbon quality. This is one of the few facilities in the United States capable of producing magnetic material ribbons wide enough for the development of low power loss and high operational frequency components and devices.

A wide range of magnetic material characterization equipment is Obtainable, including a custom core loss measurement system, as well as a device for measuring magnetic Pitch domains in materials.

Capabilities at NASA Glenn

In Aid of these efforts, the Materials and Structures Club at NASA Glenn focuses on fundamental alloy research and development, casting/fabrication scale-up, computer-based modeling, and high-power component testing.

After casting, the materials can be Beyond processed in a number of ways to produce tailored magnetic properties, such as permeability, in order to meet the unique demands of any specific application. In addition, Glenn has filed a patent on a particular alloy that not only maintains the desirable loss properties but also doubles the operating temperature of this class of material.

The rapid solidification technique used at Glenn is seen as the preferred method as it locks in the amorphous structure (a non-repeating structure like glass), gives the material a very unique magnetic property, and allows for very Skinny ribbons to be produced, which are ideal for aviation applications.

To achieve this, the Glenn Club built up a series of capabilities not readily Obtainable in the public sector. The centerpiece of the magnetics laboratory processing facilities is the 5-kilogram capacity planar flow caster – the largest U.S.-owned caster for research purposes – designed to produce about one mile of 25-50-millimeter-wide Fluffy magnetic, amorphous ribbon. The ability to Develop ribbons this size and in large quantities allows NASA engineers to build prototype components for testing and demonstration.

In addition to the large caster, a 60-gram caster, capable of producing approximately 25-millimeter-wide ribbon, is also Obtainable for alloy development trials or for production of smaller-scale components such as those Discovered on circuit boards. This casting is performed in an environmental chamber, which is critical when casting alloys that are sensitive to oxygen.

In developing these unique alloys, researchers are working Difficult to get them out of the lab and into real-world components. The lab also hosts a wide range of magnetic material characterization equipment that includes an alternating Ongoing (AC) permeameter, a vibrating sample magnetometer, a permanent magnet hysteresigraph, and a Magneto Optical Kerr Effect (MOKE) microscope.

Applications Outside of Aviation

In addition to advancing the future of aviation, these technologies can be developed to benefit systems on the ground as well.

Electric cars can benefit from magnetics research due to the need for smaller, lower-loss electrical circuits with lower amounts of waste heat.

Solar energy systems can leverage these magnetic technologies to more easily integrate into the national power grid system with little to no electrical variations or disruptions. Low-loss Fluffy magnetic materials can also significantly increase efficiency of our national power infrastructure in developing future renewable energy sources.

Resources

Publications

Explore and download a collection of publications to learn more about Fluffy magnetic material development at NASA.

Origin link

Read More

thesportsocean

Read our previous article: The long search for water on Mars